Case Studies

Environmental Benefit Analysis of Plastic Bottle Recycling Processes

We understand the challenges of producing life cycle studies for chemicals and materials commonly used by manufacturers and we are the industry leader in providing solutions for the chemical industry. Read our published, peer-reviewed life cycle inventory (LCI) of polymer (plastic) recycling processes that reduced the carbon footprint of plastic bottles by 60-70% of the original, full supply chain.The Environmental Clarity database includes six such recycling options and more than 30 polymers.

We've produced environmental profiles of the manufacturing processes and extensive supply chains of numerous pharmaceuticals. Recently we produced a life cycle analysis of Vancomycin HCl, an antibiotic used to treat certain bacterial infections. Pictured is the chemical structure of Vancomycin.

Environmental Profiles of Active Drug Ingredients

As drugmakers face growing demands from regulators, investors, and customers for climate risk and emissions disclosures the need for Environmental Clarity’s advanced life cycle inventory (LCI) data and analytic capabilities has never been greater.

Our LCI database, the largest by a factor of five, houses the most full life cycle analyses of active drug ingredients and excipients available.

We're experts in developing datasets for solvents, fine chemicals, and synthetic drugs to help fill LCI data gaps.

Our chemistry and engineering methodologies and advanced analysis provides detailed, transparent results for credible Scope 1, 2, and Scope 3 reporting, as welll as insights for improvements in manufacturing processes, supply chains, and environmental outcomes.

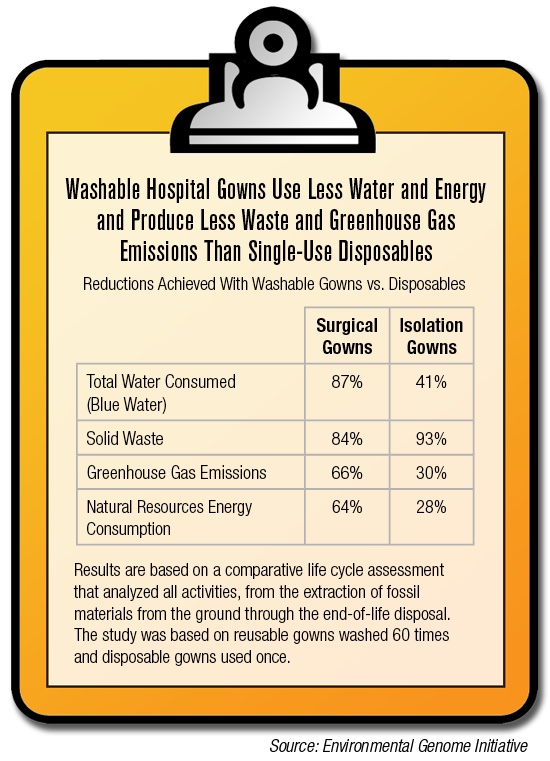

The American Reusable Textile Association (ARTA) used Environmental Clarity’s comparative LCAs to make a powerful case for washable versus single-use isolation and surgical gowns, protective garments worn by hospital personnel.

The isolation gown LCA was conducted with 24 gowns from eight suppliers representative of the overall market. The cradle-to-end-of-life analysis included all activities from natural resource extraction to manufacturing of the gowns and packaging, use and/or reuse in healthcare settings, end-of-life landfill disposal as well as laundry operations in the case of the reusable gowns. Altogether, 144 unique gate-to-gate LCIs were conducted to complete the LCA.

Environmental Clarity later examined seven reusable and 11 disposable surgical gowns representative of the market. The scope of the study covered the complete supply chain, including calculations for laundering, sterilization (if needed), and wastewater treatment operations for the reusable gowns and landfill for disposable gowns. The cradle-to-end-of-life examination required 245 LCIs.

The studies clearly showed that reusable isolation gowns and surgical gowns provide large environmental benefits versus their disposable counterparts.

Both LCAs were peer reviewed and published in professional publictions. The surgical gown LCA appeared in The AORN Journal, a journal for operating room nurses. The isolation gown LCA was published in The American Journal of Infection Control.

San Francisco–based waste solutions provider, Brightmark, needed to quantify the environmental performance of its plastic recycling technology compared to that of manufacturing plastics directly from fossil resources. Overall, our LCA found that products created through plastics recycling, like renewable fuels and wax, require only 17% of the amount of fossil fuels in the same family of hydrocarbon plastics made from virgin petroleum.

Plastic recycling was combined with the avoided waste activities to produce a cradle-to-gate impact of one metric ton of Brightmark’s total marketable products. That was compared to the cradle-to-gate impact of the virgin production required to produce the equivalent products. The the difference is the net benefit from the Brightmark process.

Overall, Brightmark’s process saved 82% of natural resource energy, 39% of carbon footprint based on U.S. waste management, 139% of carbon footprint based on regions with a 50% incineration rate, and it saved 46% in water loss.

Transparent LCI Data to Fill Data Gaps

When a Japanese government agency charged with conducting R&D to promote the country’s agriculture and food industries sought environmental LCI data for a project on crop management, it found that none of our competitors could supply the information needed.

The National Agriculture and Food Research Organization (NARO) turned to Environmental Clarity for the crop protection chemical data it required. We provided LCI data for more than eight herbicides, pesticides, and fertilizers that NARO wanted to research.

Our datasets allowed NARO visibility of the supply chains at a much higher level of transparency than previously existed and we provided process emissions throughout the supply chains, which the agency valued. One of the products for which we provided LCI data was glyphosate, the active ingredient found in the herbicide Roundup.